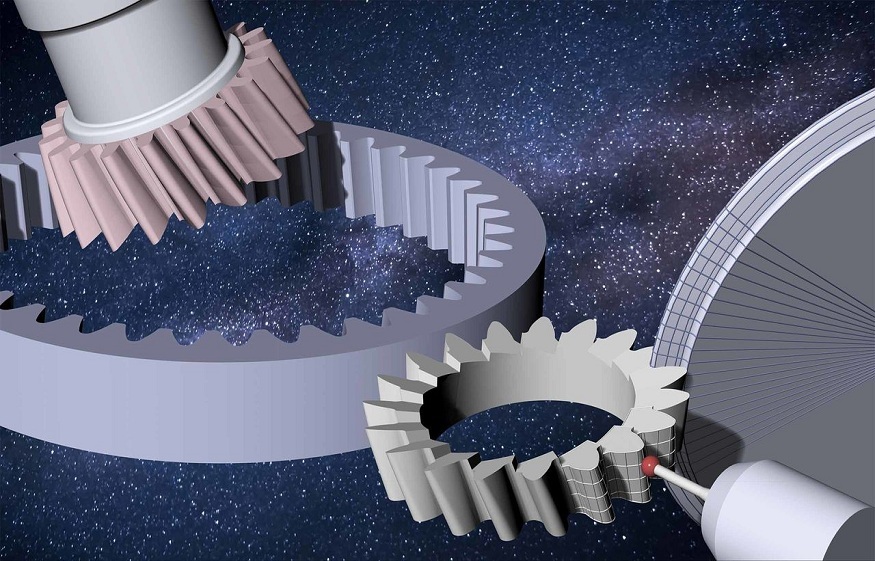

Gear cutting tools

Gear cutting tools are to create gears of various sizes and shapes. There are several different types of gear cutting tools, each suited for other applications. Some of the most common types of gear-cutting tools include hobs, shapers, and broaches. Hobs are used to cut external gears, while shapers are used to cut internal gears. Broaches are versatile tools that can be used for both internal and external gear cutting. gear cutting tools are an essential part of the gear manufacturing process. With the right gear cutting tools, you can produce high-quality gears that meet your precise Specifications. You should look at your Specifications of what you require of Gear cutting tools, gear shaper cutters.

Gear shaper cutters

Gear shaper cutters are cutting tools that are used to remove material from gear teeth to create a specific shape. Gear shaper cutters are used in a gear shaper machine, which is a type of machine tool that is used to create gears. The gear shaper cutter is mounted on a spindle and is used to cut teeth into the gear blank. The gear shaper machine can be set to cut teeth of any shape, size, or number. Gear shaper cutters are an essential part of the gear manufacturing process and are used in a range of applications, such as automotive, aerospace, and energy.

The need for Gear cutting

To produce successful results, engineers need to apply the correct cutting process to specific materialistic behavior. The development of new alloys and materials has broadened the range of products that can be machined. With this, a greater understanding of the relationship between workpiece material properties and specific cutting processes is essential to remain competitive. Gear cutting technologies are used in several industries, including automotive, aerospace, mining, and construction. In each of these industries, there are requirements for the types of gear cutting that need to be performed. For example, the automotive industry typically uses gear-cutting technologies for engine components, while the aerospace industry uses them for aircraft and missile parts. No matter the industry, gear cutting is a process that needs to be understood and mastered to produce the best results.

Cost of a good machine

As gear hobbing machines become increasingly popular, the question of cost is often raised. How much does a good gear hobbing machine cost? The answer depends on many factors, such as the size and complexity of the machine, the materials it is made from, and its features. A good gear hobbing machine can cost anywhere from a few thousand dollars to over a hundred thousand dollars. Of course, the cost of the Gear hobbing machine is only one part of the equation. You also need to factor in the cost of training, maintenance, and repairs. When all of these costs are considered, the cost of a gear hobbing machine can be very high. So we have to check the cost also.